Business

What Is the Difference Between Green and Sustainable Manufacturing

Understanding the distinction between green and sustainable manufacturing is crucial when making a positive impact in the manufacturing industry, whether as a business leader, employee, or informed consumer. In Singapore and beyond, these concepts are shaping the future of production, brand reputation, and market differentiation.

The rise of eco-conscious consumers and companies seeking to improve their environmental footprint led to an increasing focus on green and sustainable manufacturing. The two concepts often overlap but serve distinct purposes for the future of industrial processes.

Let’s learn the key differences between green and sustainable manufacturing and understand how adopting either (or both) can positively impact your brand’s long-term success.

Defining the Concepts

At first glance, “green manufacturing” and “sustainable manufacturing” may seem like two sides of the same coin. Both aim to reduce environmental impacts, promote eco-friendly practices, and align industries with global efforts toward mitigating climate change.

However, the fundamental difference lies in their scope, implementation, and long-term vision.

Green Manufacturing – A Focus on Environmental Impact Reduction

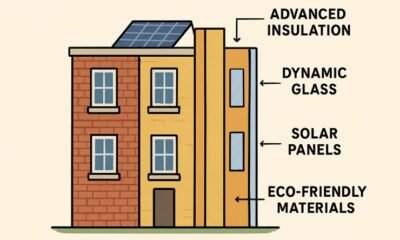

Green manufacturing refers to processes and practices that aim to minimise environmental impact by reducing waste, emissions, and resource consumption, primarily in the production process. The focus is often on eco-friendly manufacturing technologies, energy efficiency, and pollution prevention.

Green production processes are designed to use fewer hazardous materials, reduce energy consumption, and lower the environmental footprint in every possible area of production. Green manufacturing companies typically adopt:

- Renewable energy sources in production lines

- Waste reduction and recycling programs

- Cleaner production methods

- Use of eco-friendly materials

- Using energy-efficient machinery

- Reducing water consumption

These efforts are typically aimed at making manufacturing operations more environmentally friendly. Green manufacturing often involves implementing immediate, practical changes. It focuses on enhancing processes and technologies within the existing framework of the manufacturing system, with a primary emphasis on efficiency and minimising negative environmental impacts.

Sustainable Manufacturing – Long-Term Solutions for People, Profit, and Planet

Sustainable manufacturing goes a step further. It not only addresses environmental concerns but also integrates social and economic dimensions. Sustainable manufacturing processes are designed to meet present needs without compromising the ability of future generations to meet their own needs.

Sustainable manufacturing extends beyond the production process itself, encompassing the broader impact of the entire product lifecycle. From sourcing raw materials to the end of the product’s life. This approach considers:

- Environmental protection (like green manufacturing, designing products that can be reused or recycled at the end of their life cycle)

- Social responsibility (worker well-being, fair labour practices, community impact)

- Economic viability (long-term profitability, resource efficiency, ethically sourced materials)

Sustainable manufacturing is about creating value in a way that is beneficial for the planet, people, and profits, which is often referred to as the “triple bottom line.” This approach includes not just environmental impact reduction but also social and economic considerations. It adopts a holistic approach to sustainability, ensuring that manufacturing practices are economically viable, socially responsible, and environmentally sound in the long term.

While green manufacturing is more process-focused, sustainable manufacturing encompasses a broader, more holistic strategy for overall business sustainability, which includes ethical considerations alongside environmental goals.

What Is the Difference Between Green and Sustainable Manufacturing?

All sustainable manufacturing is green, but not all green manufacturing is fully sustainable. The key difference lies in scope and intent:

Green manufacturing is primarily focused on reducing the negative environmental impact of manufacturing processes.

Sustainable manufacturing encompasses green manufacturing principles but also includes social and economic factors, aiming for a holistic approach to long-term viability.

Why Should This Distinction Matter to You?

Both green and sustainable manufacturing are integral to the movement toward more environmentally responsible production in today’s industries. However, they serve different purposes and contribute to the broader goal of reducing global environmental impacts in unique ways.

This comparison table outlines the key differences and benefits of each approach, helping your business identify how it can reduce environmental impact and future-proof operations.

| Aspect | Green Manufacturing | Sustainable Manufacturing |

|---|---|---|

| Benefit to Business | Improves brand reputation, attracts eco-conscious customers, and provides cost savings through operational efficiency. | Builds a strong, resilient brand, differentiates from competitors, and ensures long-term market viability. |

| Strategic Business Value | Helps companies position themselves as eco-friendly, improving communication with customers and investors. | Helps future-proof businesses against regulatory changes and market shifts, building trust with a broader customer base. |

| Examples | Solar panels, eco-friendly packaging, energy-efficient equipment, and waste reduction. | Circular economy practices, ethical sourcing, carbon neutrality, and fair labour practices. |

| Real-World Example (Singapore) | Panasonic's solar-powered factory. Source: https://www.coolingpost.com/world-news/panasonic-factory-employs-solar-pv/ | Sembcorp's integrated water plants and circular economy initiatives. Source: https://www.siww.com.sg/landing-page/past-events/siww2022/programme/technical-site-visits/sembcorp-newater-plant |

| Customer Appeal | Attracts eco-conscious customers seeking environmentally friendly products. | Attracts customers who value ethical production, long-term environmental responsibility, and social equity. |

The Role of Technology and Innovation

Advancements in green manufacturing technologies are making it easier for companies to reduce their environmental footprint. However, sustainable manufacturing processes also require:

- Transparent supply chains

- Ethical sourcing of materials

- Ongoing stakeholder engagement

You can drive innovation that benefits both business and society by combining green manufacturing with broader sustainability goals. As consumers and businesses become more focused on reducing their environmental impact, they are increasingly drawn to companies that prioritise eco-friendly manufacturing.

How to Get Started: Practical Steps

Adjusting your business production to fit eco-friendly or sustainable manufacturing can be a powerful way to differentiate your brand in a competitive marketplace. Consider incorporating sustainability-focused messaging into your production lines and reach your ideal consumer through relevant marketing campaigns, emphasising your efforts to adopt green production processes, source materials responsibly, and reduce your carbon footprint.

If you’re inspired to make a difference, consider these steps.

- Assess your current operations: Identify areas where green production and sustainable manufacturing processes can be implemented.

- Set measurable goals: For example, reduce energy use by 20% or achieve zero waste to landfill.

- Engage your team: Foster a culture of environmentally conscious manufacturing.

- Communicate your efforts: Share your journey with customers and stakeholders to enhance your brand reputation.

Use your eco-friendly and sustainable practices as key selling points in your communications. Educate your audience on the value of green and sustainable manufacturing, helping them understand why these practices are not only good for the planet but also beneficial for consumers.

Transparency about your processes and commitment to sustainability demonstrates a company that cares about the future of both the environment and the people it serves.

The Path Forward

You’re better equipped to champion positive change in the manufacturing and sustainability landscape when you understand the difference between green and sustainable manufacturing. Adopting eco-friendly manufacturing practices and striving for holistic sustainability can set you apart as a forward-thinking, responsible leader.

Your commitment to sustainability and manufacturing excellence builds lasting trust with your customers, making your brand a beacon of positive change in the industry. Both approaches are crucial in advancing the manufacturing industry’s commitment to sustainability, and they present valuable opportunities for businesses to enhance efficiency and attract eco-conscious customers.

-

Quotes3 years ago

Quotes3 years ago53 Motivational Gym Quotes to Fuel Your Workout

-

Quotes10 years ago

Quotes10 years ago50 Most Powerful Quotes Ever Spoken

-

Motivation5 years ago

Motivation5 years ago4 Fun New Hobbies To Try This Year

-

Quotes1 month ago

Quotes1 month ago100 Motivational Quotes to Inspire You in 2026

-

Quotes2 years ago

Quotes2 years ago43 Inspirational Quotes About Thoughts

-

Quotes3 years ago

Quotes3 years ago105 Motivational Quotes by Famous People

-

Quotes7 months ago

Quotes7 months ago100 Motivational Quotes to Start Your Day with Positivity

-

Education1 year ago

Education1 year agoHow to Motivate Yourself to Study: 6 Proven Techniques